LTCC (Low Temperature Cofired Ceramic)

RF Components for High Frequency Wireless Communication

Low Temperature Co-fired Ceramic (LTCC) technology devices are multilayer structures made with ceramic materials. The processes involve laser drilling to create vias, filling them with metal slurry to provide connections between layers, screen printing the patterns based on the circuit design, stacking layers accordingly, and sintering at 850~900°C to make small and compact components. This technology can integrate multiple passive components (inductors, capacitors, etc.) into one small device which is suitable for consumer thin and lightweight electronics. At the same time, ceramic materials have high-Q characteristics at high-frequency that are suitable for wireless communication applications, such as GPS, Bluetooth, WiFi, 5G mobile phones, etc.

ABC has introduced new high-precision production equipments for LTCC and assembled a team with experience in materials, processes, and design. At ABC, we have the capability to customize and develop new LTCC products for our customers. For more detailed information, please product inquiry on top or fill out the inquiry form below, we will get back to you as soon as possible.

ABC LTCC 6G n104 New Products

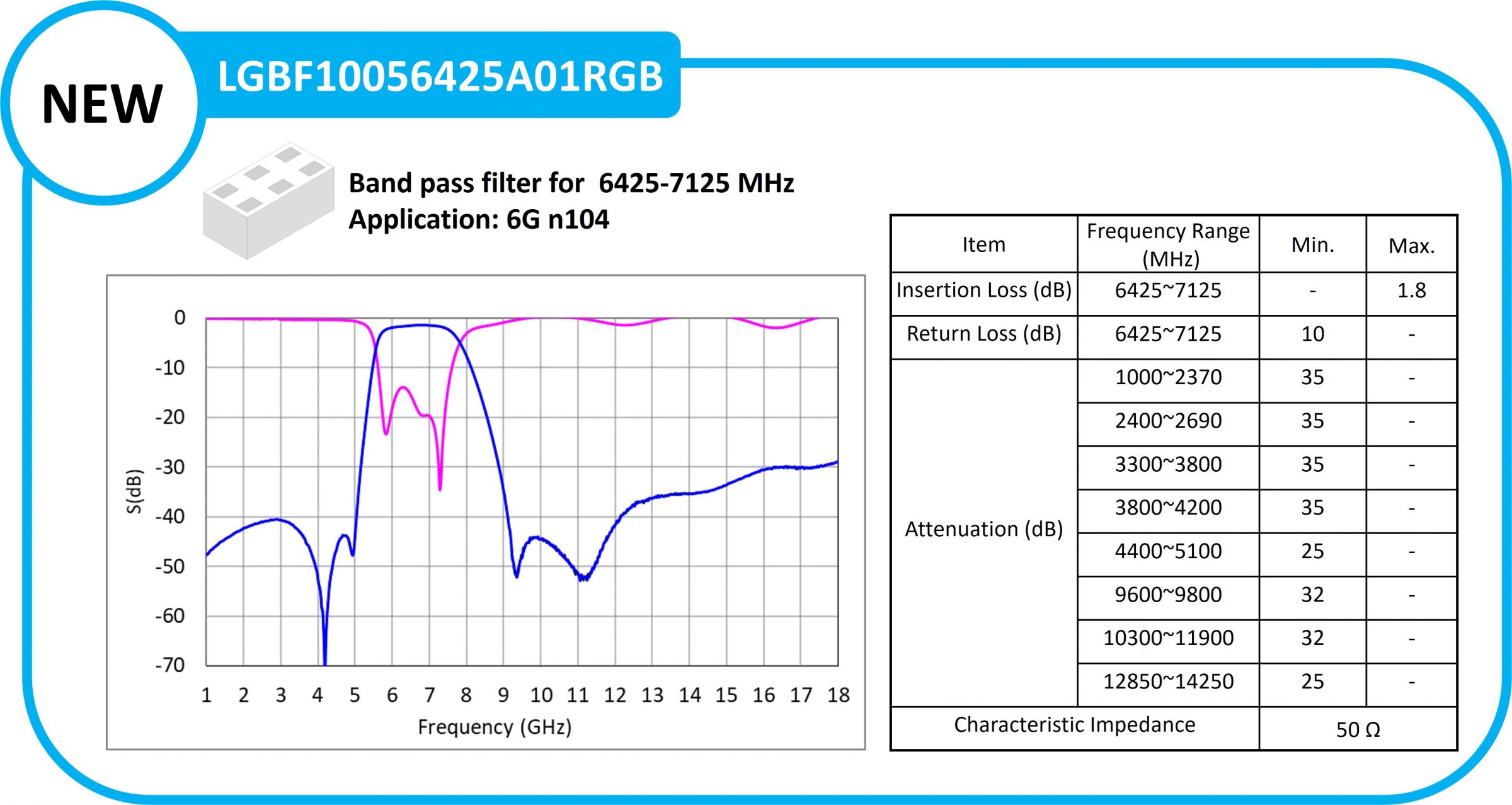

With the development of cloud computing, big data, and AI, the demand for 5G communication efficiency continues to increase. In addition to the 3.3-5 GHz (n77, n78, and n79) bands, the 5G FR1 spectrum continues to develop in the high-frequency range. Recently, 3GPP defined the band n104 (6425-7125 MHz) as the global IMT band standard and used for the next generation 5G advanced/6G communications. Currently, countries around the world are actively deploying 6G, and it is expected to be commercialized around 2030.

ABC LTCC team also developed a 1005-size band pass filter LGBF10056425A01RGB for the n104 band to provide customers with solutions in the early stages of design.

ABC LTCC UWB New Products

Ultra-wideband (UWB) is a short-range, low-power wireless communication technology. Compared with Wi-Fi and Bluetooth, UWB has higher accuracy and security, and is particularly suitable for applications such as centimeter-level precise positioning and vehicle intelligent systems.

UWB technology is introduced into Apple and Samsung’s flagship smartphones and the latest smart watches, Apple Watch and Google Pixel Watch. In the automotive industry, major automakers such as Tesla, BMW, Audi, and Benz have incorporated UWB into their smart car keyless systems, which not only improves vehicle safety but also improves user experience. Garmin also uses UWB technology to detect child presence detection (CPD) in the smart cabin exhibited at CES. It can detect which seats are occupied and classify them as children or adults based on breathing patterns to ensure that sleeping children are not forgotten in the back seat.

In response to the demand, our company has specially developed two filters (LGBF16087240A01LGB & LGBF16087987A01RGB) suitable for UWB Ch5 and Ch9 (6240-8240 MHz) and Ch9, Ch10 and Ch12 (7737-9235 MHz).